Monitor

RMS delivers instant visibility into your assets' real-time performance, tracking crucial data like energy production and equipment status. Proactive alerts swiftly detect anomalies, ensuring a holistic monitoring solution for solar panels or industrial equipment.

Control

Streamline operations with RMS's remote management, reducing on-site visits and adapting configurations based on real-time insights. The user-friendly interface caters to various technical expertise levels, enhancing overall control efficiency.

Business Insight

RMS empowers decision-making through cutting-edge analytics, providing valuable operational insights. From data-driven decisions to predictive capabilities, RMS optimizes processes, allocates resources effectively, and ensures proactive measures for business continuity.

Hardware

Your All-in-One Remote Monitoring & Control Solution

Vraious connectivity options, including GPS, offer a comprehensive range of features, ensuring the Remote Monitoring System's adaptability to various networking scenarios and providing precise location tracking capabilities.

- Utilizes the SIMCOM A7672S 4G LTE Module for reliable and high-speed cellular connectivity.

- Equipped with the ESP32 32-bit WiFi Controller, enabling wireless communication for local network connectivity.

- Incorporates GPS technology for accurate location tracking.

Our Remote Monitoring System is an advanced solution crafted to optimize the efficiency, reliability, and overall performance of renewable energy installations and various industrial applications. Whether you're overseeing a small-scale residential setup or managing extensive industrial facilities, our system offers real-time insights and control, ensuring seamless monitoring and operation of your energy assets.

Our platform stands out for its complete compatibility with the Pradhan Mantri Kisan Urja Suraksha evam Utthan Mahabihiyaan (PM KUSUM) project requirements. Specifically designed to seamlessly integrate with various components essential to the PM KUSUM initiative, our platform ensures a hassle-free experience for users involved in Pump Control, Energy Meter, Inverter, String Combiner Box (SJB), and other relevant systems.

ESP32 MCU

ESP32 the 32-bit Controller serves as a powerful and versatile microcontroller designed specifically for wireless communication and IoT applications.

SIMCOM A7672S 4G LTE Module

The system ensures high-performance 4G cellular connectivity and GPS. This module enables reliable and high-speed data transmission, allowing the Remote Monitoring System to operate efficiently across diverse environments.

RS485 and RS232 communication protocols

With support for both RS485 and RS232 communication protocols, the system offers flexibility for various industrial applications. The optional isolation of these communication channels minimizes electrical interference, contributing to enhanced reliability in data transmission.

Micro SD Card slot

The inclusion of a Micro SD Card slot further expands the system's capabilities, allowing for local data storage. This feature enables the system to store and retrieve data locally, providing an additional layer of versatility in handling information.

Nano SIM slot

The Nano SIM slot is integrated to support cellular network functionality. This inclusion enables seamless communication over cellular networks, contributing to a more versatile and comprehensive solution for the Remote Monitoring System.

RTC (Real-Time Clock)

On-board, the system boasts an RTC (Real-Time Clock) and 32k EEPROM, ensuring accurate timekeeping and providing non-volatile storage for critical information. This feature allows the system to retain crucial data even during power cycles.

W5500 Ethernet Module(Optional)

he W5500 Ethernet Module is integrated for scenarios requiring wired networking. This component enhances connectivity options, providing a reliable foundation for data transmission in scenarios where wired connections are preferred or necessary.

4 Digital Isolated Inputs

For enhanced monitoring capabilities, the system incorporates 4 Digital Isolated Inputs. These inputs allow the monitoring of external signals, expanding the system's capability to interface with various sensors and external devices.

2 Digital Outputs

The system includes 2 Digital Outputs that enable the Remote Monitoring System to actively control external devices or relays based on the monitoring data gathered.

Software

Empowered by Artibraino's cloud-based and award-winning t2iot platform, the Remote Monitoring System (RMS) stands out as a cutting-edge solution for diverse applications. This platform provides an omnichannel experience, employing OAuth2-based secure and reliable connectivity. The integration of role-based authentication and control within RMS ensures a secure environment. Users can seamlessly interact with the system through various channels, including web browsers, mobile applications, and REST API-based integration. This versatility enhances user accessibility and accommodates different preferences for interacting with the monitoring system..

Real-Time Monitoring

Attain immediate visibility into the performance metrics, be it monitoring solar panels or any industrial equipment in your system. Our monitoring system furnishes real-time data, ensuring quick identification and resolution of any issues that may arise in your operations, fostering efficiency and minimizing downtime.

Remote Diagnostics

Troubleshoot issues remotely with our advanced diagnostic features, minimizing the necessity for on-site visits. Access detailed diagnostics for various industrial assets, reducing operational costs and enhancing overall maintenance efficiency across your infrastructure.

Performance Analytics

Delve deep into performance analytics, applicable not only to solar arrays but also to diverse industrial machinery. Track trends in energy production, assess the impact of external factors, and identify optimization opportunities. Leverage our comprehensive analytics and reporting tools to make informed decisions for enhanced operational efficiency.

Fault Detection and Alerts

Receive prompt alerts for anomalies or faults within your infrastructure, whether it's related to solar panels or any other industrial component. Whether detecting a malfunction or a decrease in output, our system notifies you instantly, facilitating a swift response and reducing disruptions.

App-Based Control

RMS revolutionizes user accessibility and control, offering an intuitive and feature-rich app-based interface. This innovative approach to control enhances the overall user experience, making the management of your energy system, whether solar or industrial, more convenient and efficient.

MQTT(s)

Supporting MQTT(s) ensures efficient and lightweight communication, ideal for resource-constrained devices in diverse industrial applications..

HTTP(s)

Compatibility with HTTP(s) provides seamless integration with web-based services, enhancing the system's adaptability in connected environments.

FTP

The inclusion of FTP enables secure and reliable file transfers, crucial for industrial applications requiring firmware updates and data exchange.

Modbus

With Modbus support, the system enhances compatibility with SCADA systems, providing a standardized communication protocol for industrial automation.

Over-The-Air (FOTA)

The Firmware Over-The-Air (FOTA) support within the system guarantees a streamlined process for updating device firmware. This functionality eliminates the need for physical access to devices, enabling remote and hassle-free firmware upgrades.

SPI

Support for SPI facilitates synchronous serial communication, expanding connectivity and enabling seamless interaction between devices in industrial setups.

I2C

Incorporating I2C support allows for a two-wire serial bus, accommodating a variety of sensors and devices, thereby enhancing versatility in industrial environments.

Experience the future of intelligent monitoring & control

Elevate your connectivity, control, and insights—take the leap towards intelligent monitoring. Connect with us to revolutionize your operations now.

Some Applications

Unlock new possibilities with our Remote Monitoring and Control System (RMS), featuring advanced capabilities to revolutionize your operations. Our RMS goes beyond by offering 4G connectivity for seamless communication, coupled with real-time location tracking. Additionally, it supports key protocols such as Modbus, SPI, and I2C, ensuring seamless integration with a variety of sensors and actuators. This comprehensive solution empowers you to monitor and control processes with precision, enhancing efficiency across diverse applications. Experience the future of connectivity and control with our feature-rich RMS.

Empowering Renewable Energy

SolarWhether overseeing agricultural pump control, monitoring energy consumption, or optimizing the performance of inverters and combiner boxes, our platform's seamless compatibility effortlessly integrates into your existing infrastructure. This not only streamlines implementation but also elevates the overall efficiency and effectiveness of your operations. Aligned perfectly with the goals and requirements of the PM KUSUM project, our platform is designed to enhance your workflow.

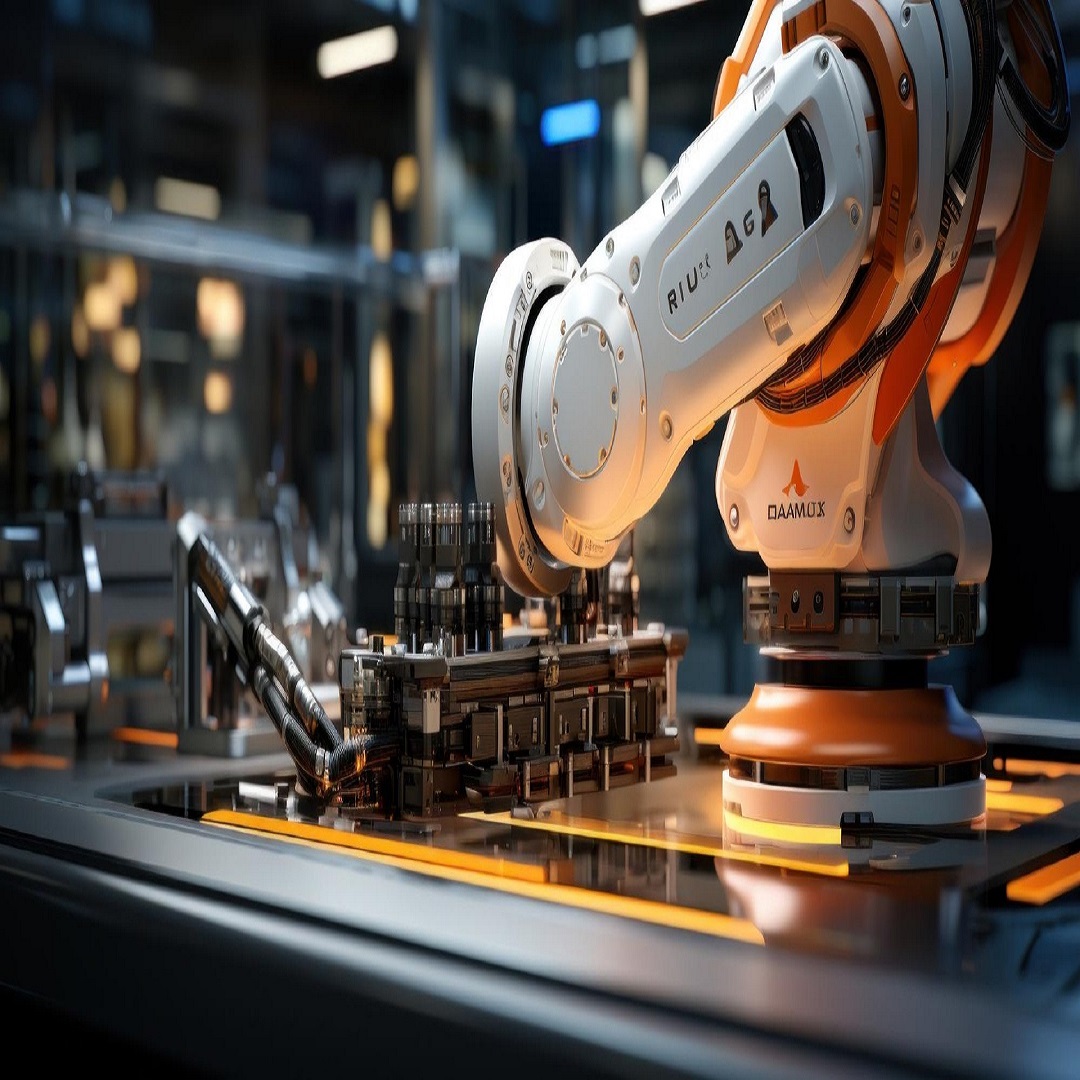

Industrial Manufacturing

Monitor and control machineryIn the realm of industrial manufacturing, our IoT-based remote monitoring and control system stands as a transformative solution, seamlessly integrating into diverse manufacturing environments. With robust support for industry-standard protocols such as Modbus and versatile connectivity options including 4G, WiFi, and LoRA, our platform ensures efficient data collection from sensors and enables precise control through Modbus, UART, SPI, and I2C mechanisms. This comprehensive approach empowers industrial facilities to achieve unparalleled automation, optimizing processes, enhancing machinery efficiency, and facilitating predictive maintenance. The utilization of advanced communication protocols and connectivity options not only streamlines data acquisition but also provides a solid foundation for real-time decision-making, contributing to increased operational agility and overall productivity in industrial manufacturing settings.

Logistics and Supply Chain

CargoIn the realm of Logistics and Supply Chain, our RMS proves indispensable, revolutionizing the management of goods and ensuring their safe and efficient transport. Real-time location tracking forms the backbone of our system, providing granular insights into the movement and status of shipments. For industries dealing with perishable goods or sensitive medical supplies that require specific temperature maintenance, our platform integrates advanced temperature sensing capabilities. This feature guarantees that your products are transported under optimal conditions, adhering to stringent temperature requirements and minimizing the risk of spoilage. With seamless 4G connectivity, our RMS establishes a robust communication network, enabling instant access to critical data and ensuring uninterrupted monitoring and control capabilities.Embrace a new era of precision and control in your logistics endeavors with our cutting-edge IoT solution.

Frequently Asked Questions

A: Our system offers real-time monitoring, fault detection and alerts, performance analytics, remote diagnostics, environmental monitoring, and app-based control for efficient management of your solar energy system.

A:No, we are not directly monitoring solar panels. However, if you have integrated electronics, we interface with them using Modbus, SPI, or I2C to provide real-time access and control.

A: The system features the ESP32 32-bit WiFi Controller, SIMCOM A7672 4G LTE Module, W5500 Ethernet Module, RS485/RS232 with optional isolation, and various other components to ensure seamless and efficient monitoring and control.

A: The system supports a range of protocols such as MQTT(s), HTTP(s), DHCP, FTP, Modbus, SPI, I2C, etc., ensuring compatibility with diverse industrial applications.

A: Ensure stable power supply, prevent electrostatic discharge, follow pinout and connection guidelines, avoid extreme environmental conditions, and implement proper security measures for reliable performance.

A: In case of any issues or difficulties, you can reach out to our technical support team at contact@artibraino.com for prompt assistance and resolution.

A: A Remote Monitoring System is a technology that allows users to monitor and manage devices or systems from a distance, often through the use of sensors, communication networks, and data visualization tools.

A: Yes, our Remote Monitoring System fully supports MQTT (Message Queuing Telemetry Transport) protocol, providing a reliable and lightweight communication method for IoT devices and applications.

A: You can access the monitoring data through our web-based interface or mobile application. Simply log in with your credentials to view real-time data, analytics, and historical trends.

A: Yes, our Remote Monitoring System is designed to be compatible with a wide range of sensors. It supports various communication protocols, allowing integration with sensors for temperature, humidity, pressure, and more.

A: Our system supports a variety of protocols including MQTT, HTTP/HTTPS, CoAP, and SNMP for seamless communication with diverse devices and platforms.

A: Yes, the system is designed to integrate seamlessly with sensors using different communication protocols such as Modbus, and LoRaWAN.

A: Absolutely, our system supports various wireless connectivity options including Wi-Fi, Bluetooth, and cellular networks for flexible deployment in different environments.

A: Yes, our Remote Monitoring System is designed to seamlessly integrate with devices supporting Modbus communication. You can use it to configure and monitor various registers in your solar water motor pump for remote troubleshooting and efficient management.

A: Yes, our Remote Monitoring System is designed to seamlessly integrate with devices supporting Modbus communication, including solar inverters. You can use it to configure and monitor various registers in your solar inverter for remote troubleshooting and efficient management.

A: The RMS efficiently monitors Solar System Performance by continuously measuring and recording crucial parameters such as DC Voltage, DC current, AC output Current, Power, Drive frequency, Energy, etc. It ensures accurate and real-time data for effective system management. These Parameters need to be available to be fetched from Modbus address.

A: The RMS maintains a comprehensive record of Pump Performance, including Running Hours and Water Discharge (Output), providing valuable insights into the operational status of the pump for efficient monitoring and maintenance. Please note that this need to be supported by underlying system , parameters like water discharge either need to stored in pump which RMS can fetch or vendor need to provide calculation parameters for the same.

A: The RMS rigorously monitors performance metrics, such as % of Device Connectivity and % of Data Availability, to guarantee a highly reliable and connected system, ensuring seamless data flow and accessibility.

A: The RMS utilizes advanced technology withinpubild GPS resystem to capture real-time latitude and longitude with exceptional accuracy (less than 10m horizontal), ensuring the system's stability and preventing any unauthorized movement.

A: All information is available in dashboard, the RMS promptly notifies and records faults related to Pump Operation, Solar generation, and Controller/Drive issues, ensuring quick response and effective troubleshooting for optimal system performance.

A: Consumer Management encompasses crucial details such as Name, Agriculture details, Service No., and Contact Details, facilitating personalized service and effective communication with consumers. It also store address of the customer for convenience support.

A: The RMS meticulously manages assets by recording essential information such as Ratings, Serial Number, Make, Model Number, Geo Location, IMEI number, and ICCID, ensuring effective tracking and maintenance.

A: Complaint and Ticket Management seamlessly integrates into the centralized monitoring software platform, providing a comprehensive system for efficient handling and resolution of issues reported by users.

A: The Consumer Mobile Application offers functionalities such as Generation monitoring, Running Hours tracking, Water Discharge analysis, and Complaint logging, providing users with a user-friendly interface for effective system interaction.

A: Pump Controller Connectivity uses UART/RS485 MODBUS RTU protocol, Remote Connectivity utilizes GSM/GPRS/2G/3G/4G cellular connectivity, Local Connectivity employs Ethernet/Bluetooth/Wi-Fi, and Sensor Connectivity supports Analog and Digital inputs with 0.1% accuracy for seamless and interoperable communication.

A: The RMS offers versatile operational modes, including Remote Mode (for remote control via mobile app or SMS), Auto Mode (automatic control based on sensor data), Timer Mode (scheduled operation using the mobile app), and Manual Mode (on-field manual control), providing flexibility and customization for users. Please note that Underlying device need to have support for the same.

A: The RMS supports various communication modes, such as Push Data on Event/Notification (for real-time updates), Push Data Periodically (configurable intervals for crucial solar pump parameters), and Command on Demand (for remote control or configuration updates), ensuring efficient and timely data transmission.

A: The RMS utilizes the MQTT and HTTPS protocol for data transmission, enabling seamless communication with thousands of systems and ensuring a robust and scalable network for effective monitoring and control.

A: The RMS ensures secure communication by implementing encryption through TLS/SSL/X.509 certificate and follows IoT protocol-based Authentication and Authorization, providing a robust security framework for data transmission and system access. Powered by Artibraino t2iot plateform it offers banking grade security and end to end encryption.

A: The RMS provides data in the JSON message format, meeting the requirements of the implementing agency for its flexibility and compatibility. This format ensures seamless data integration and processing for effective system management.

A: The RMS features local data storage on SD card in case of unavailability of a cellular network, with a duration of one year. It ensures that data is securely stored and can be pushed to the central server upon network availability, preventing any disruption in pumping operations.

A: RMUs receive configuration updates Over-the-Air, facilitating easy updates of parameters such as IP, APN, Data logging Interval, Set Points, etc. This ensures the adaptability and efficiency of the system without disrupting pumping operations.

A: The RMS features a secure software updating process, including "Programming over the Air" on the SIA server. Measures are in place to prevent disruption during updates, ensuring continuous pumping operations even without the presence of an SD card.

A: The RMS is connected to the Solar Energy Data Management Platform of the implementing agency, ensuring seamless integration and data flow. This connection plays a crucial role in consolidating and managing solar energy data for efficient monitoring and analysis.

A: Yes, the RMS fully supports Programming Over the Air (POTA) for RMU configuration updates. This includes the seamless updating of essential parameters such as IP, APN, Data logging Interval, Set Points, etc. POTA ensures efficient and flexible updates without causing disruptions to pumping operations.

Contact

Unlock the potential of our advanced RMS, designed to meet and exceed the requirements of the PM-KUSUM project and beyond. Experience the future of industrial efficiency – connect with us today! .